Our Solutions

STACKING THE DECKS

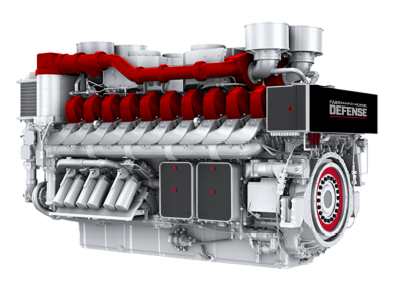

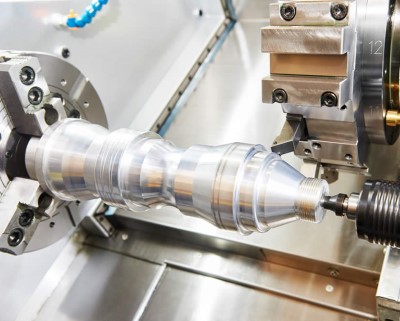

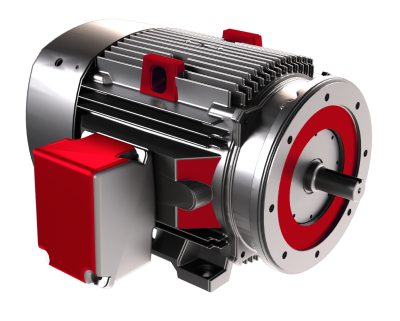

Fairbanks Morse Defense is the leading provider of original equipment for the naval defense industry. In addition to the naval defense industry, FMD also provides OE equipment commercially.

Parts & Service

Fairbanks Morse Defense offers an extensive portfolio of services to optimize performance, ensure reliability, and extend the life of your fleet - from the day its commissioned and for the many years that follow. Learn more about what our custom solutions can do for you.

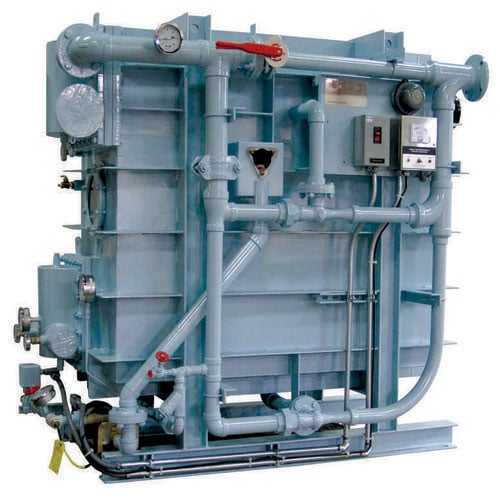

Commercial Solutions

In addition to the defense industry, Fairbanks Morse Defense also works with the commercial industry. Our commercial customers can include municipal and nuclear power plants, hospitals, universities, and international stationary power applications.

Ready to get started?

Contact us today to request a quote or get more information on any of our solutions and services.